BELPANEL

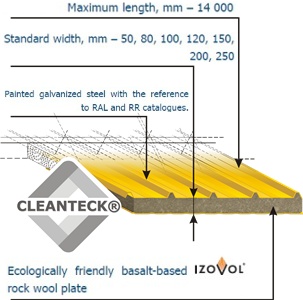

Core, made of the best fire resistant and effective IZOVOL basalt rock wool boards is the base of three-layer BELPANEL panels. It’s protected by facing layers from both sides: profiled galvanized and painted steel. Firm joint of three layers is provided by top-grade glue. Solid adhesion of steel lining and insulant guarantees higher strength and heat insulating characteristics of BELPANEL sandwich panels.

Sandwich panels are divided in two types, according to the assignment – wall and roof panels. Wall sandwich panels can be manufactured with different type of profiling: micro profile, streamlined profile, wedge groove and 2 types of standard profiling. Also the Customer can choose one of two types of locks: Z-lock and hidden screw. BELPANEL roof panels can also be manufactured with different type of external profiling. BELPANEL specialists developed and patented Corner sandwich panels (Russian patent №35413) with the additional protection function, which avoids cold jointing.

High quality IZOVOL basalt plates, used in production of BELPANEL panels are qualified as incombustible material, which allows you to use the panels as a boundary fire barrier. “E” index means the loss of structural integrity and “R” index means the loss of loaded capability over affective period in minutes. On application of 100mm thickness wall sandwich panels, EI 90 standard means that fire endurance is 90 minutes which corresponds to EI 30, EI 45 and EI 60 certificates.

Panel type | Panel thickness, mm | |||||

80 | 100 | 120 | 150 | 200 | 250 | |

Specified limit of fireproof | ||||||

Wall panels | EI 60 | EI 90 | EI 150 | |||

Wall panels | Not recommended | EI 150 | ||||

Wall panels | Not recommended | EI 150 | ||||

Roof panels | RE 30 | RE 45 | RE 60 | |||

Note: | Limit of fire propagation for all the structures is 0 cm. | |||||

Using BELPANEL three-layer sandwich panels for construction, you depress the cost of building and exploitation of your facility. Thermotechnical characteristics of BELPANEL panels are far beyond all the traditional materials of construction. 100 mm thickness sandwich panels has the same properties as 1195 mm thickness brickwork of hollow brick, 1445 mm thickness brickwork of loam brick and 1570 mm thickness brickwork of lime brick. Firm and tight joint exclude cold jointing.

High efficiency IZOVOL rock wool plates are the base of BELPANEL sandwich panels.

Unique and patented ECOSAFE technology is used in the process of manufacturing of IZOVOL rock wool plates, which allows obtaining melt without coke and furnace slag. The highest quality of melt assured by using the unique melting unit, which secures sustainable viscosity, liquidity and keeps the uniform temperature of melt, allowing obtaining IZOVOL products with the best thermal conductivity performance and better physical and mechanical properties. These factors guarantee durability of product as well as maximum efficiency, safety and surety.

Focusing on the Customer, Company produces high efficiency wall and roof BELPANEL sandwich panels, capable to complete different tasks in building industry.

- External casing of buildings and facilities;

- Walling and roofing;

- Internal walls;

- Sound barriers;

- Safety curtains.

Unique properties of high efficiency basalt-based IZOVOL rock wool, application of BELPANEL sandwich panels assure ideal comfort inside the building.

BELPANEL sandwich panels are passing stringent tests for strength properties.

Modern material of construction should pass the highest standards of fire safety, keeping comfort inside of the building and securing proper noise insulation. All types of sandwich panels are subjected to stringent tests, according to CTO 03-05 (developed by FSI). Tests are made for strength characteristics, not on the plate itself, but on lamellae:

- Compression strength test;

- Tensile strength test;

- Shearing strength test.

Average value for compression strength test of IZOVOL wall plates with 105 kg/m3 density is 102,38 kPa, which is 46,25% higher than specified value; tensile strength test is 106,3 kPa, which is 55,3% higher than specified value; shearing strength test is 74,61 kPa, which is 49,22% higher than specified value.